Taking a Look at Vision Systems for Industrial Automation

6 min read

To see is to understand. We say things like “I see what you mean” and “I had to see it to believe it” because, at a fundamental level, sight is the first way that we begin to learn about the world, and it remains the primary way that we gather information throughout our lives. On the plant floor, this often equates to checking products for defects, spatial tasks like picking and sorting, and using sight to drive and guide machinery.

What if those machines could see for themselves?

As the field of vision systems exits its nascency, as more advanced cameras and better AI software goes from the lab to the factory, manufacturers and other industries are integrating vision systems to improve productivity, reduce costs, and create consistent, high quality products. And, with companies both large and small offering plug-and-play vision systems at a reasonable price, this technology is now available for organizations of all sizes, not just those that can afford to hire a full-time data science team.

If you’re interested in beginning to integrate vision into your industrial automation pipelines but not sure how to get started, we’ve got you covered. Instead of focusing on the technology and how it works, we’re going to show you value-centered use cases that other manufacturers are already using to great success.

#1: Inspection

The simplest and fastest way to get started with vision systems for industrial automation is inspection and quality control (QC). Just like we can train employees to spot surface defects, find shape defects, or notice missing components, we can train vision solutions to automate these tasks. For instance, Swedish food manufacturer Dafgards uses vision to spot defects and anomalies in its pizza production lines to guarantee even cheese distributions, prevent exposed sauce patches, and stop the wrong toppings from ending up on their pizzas.

They were able to achieve this with Amazon Lookout for Vision, an AWS service that’s widely available and requires as little as 30 labeled images to start running. Instead of having to program the application themselves, they only needed to provide a few dozen pictures of imperfect pizzas for the system to begin to recognize them. On top of that, as the system continues to operate and people confirm or deny the vision system’s diagnoses, it continues to learn and improve. Other major solutions, such as NVIDIA TAO, require slightly more programming to work while still providing deep learning models that are already tuned and optimized.

For processes that require a high degree of precision on small, delicate, or moving objects, manufacturers can also use line scan technology. This type of camera scans objects as they pass through the “curtain” that makes up its field of vision, creating a pinpointed inspection station that’s significantly more sensitive than an ordinary camera.

It’s also important to remember that vision for QC does not entirely replace human inspectors. Rather, instead of having to check each and every product as it comes down the line, an inspector can check only the ones that the vision system flags as potential candidates. The human in the loop is our last line of defense against defects and imperfections, and, for all the progress that’s been made on vision technology, we still don’t recommend switching to 100% automated QC.

#2: Process Control

Vision systems are also revolutionizing process control by enabling more automated actions on the production line. At its core, industrial automation uses a programmable logic controller (PLC) to drive automated actions, the outputs, by processing real-time data, the inputs. As a result, better inputs lead to faster, more reliable automation. Alongside the Industrial Internet of Things (IIoT), vision systems are part of a new class of better inputs for process control.

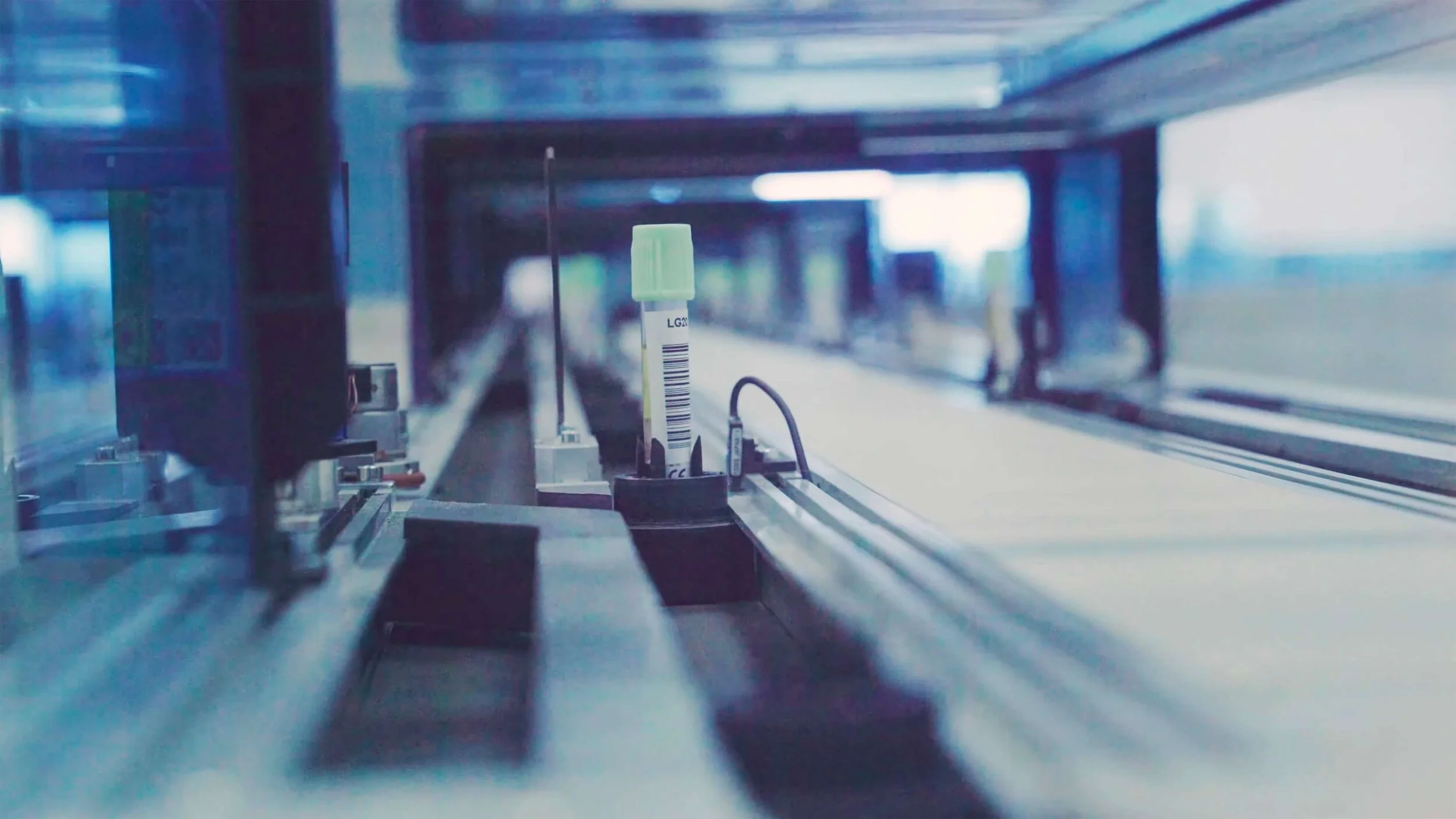

Common tasks include analysis, tracking, sorting, and measurement. This can entail using a flexible transport system that takes different products to different production areas based on visual qualities, or it can mean speeding up warehouse logistics by categorizing items and guiding technicians in where to put them.

David Greenfield at Automation World provides a concrete example: “Referencing a vision system machine learning application using Ignition at Frito-Lay, McClusky [Co-director of Sales Engineering at Inductive Automation] said the company applied it to an area of a line where a scale was located to weigh the potatoes. Frito-Lay wanted to use the vision system to determine the density of the potatoes on the line so that cook times could be adjusted accordingly for each batch. They were able to do this successfully, allowing them to eliminate dumping a portion of potatoes for weighing.”

This example highlights one of the key advantages of vision systems: flexibility. By using vision systems to understand differences in materials and products, we can drive improved automation that takes these variables into account without us having to write code for each and every scenario.

#3: Robotics

Taking flexibility and automation one step further, vision systems are proving crucial for today’s generation of industrial robots. New 3D sensing technologies, such as Photoneo's Parallel Structured Light sensors, enable robots to scan dynamic scenes that include objects in motion, a feat that’s as difficult as it is useful. Especially for mobile robotics such as Automated Guided Vehicles (AGVs) and other collaborative robots (cobots) that need to navigate changing environments while avoiding collisions and preventing injury, this technology is a true game changer.

“The targeted applications are any that require high resolution and accuracy and, at the same time, a moving scene,” says Tomas Kovacovsky [CTO at Photoneo]. “That includes vision-guided robotics in manufacturing and logistics.”

The key takeaway is that these robots with vision are much more general purpose than those fit for specific environments. While a blind robot will always follow the exact sequence that it’s programmed to do, a robot that can see will adapt, change course, and more easily fit into different scenarios. For instance, instead of having to completely reprogram the robot to do a different job, we can set it up much more quickly and with much less coding.

Cobots in particular are harnessing the power of vision to great effect. For example, Techman collaborative robots even come standard with a vision system built-in. These assistive machines are relatively low-cost, boast a general ease of use, are easier to integrate, and require less technical skills to program. These advances enable more small to medium sized enterprises to leverage this technology.

Conclusion

Vision systems are driving growth and creating new opportunities for automation across a variety of sectors, but one through-line that we want to highlight is the fact that these technologies are not replacing human workers. While many automation vendors get caught up in the hype of “automate everything!”, our experience shows us that this isn’t how it shakes out in reality.

Between keeping a human in the loop for inspection to cobots that assist and augment employees, vision-enabled automation technology is more about giving us an extra set of eyes and hands than building the completely autonomous factory of the future. It’s about finding ways to make your employees safer and more productive.

That’s where working with a trusted systems integrator is key. We analyze your current production lines, look for pain points and opportunities, account for available technologies and budgeting, and draw up a road map that takes you from where you’re at now to where you want to go. Want to get started? Reach out to us.